Clothing changes both as a reflection of society and sometimes as a predictive force for what is to come, as in the case of the burgeoning field of wearable technology—the one that goes beyond smartwatches and that will likely soon envelop far more than our wrists.

The creation of clothing is no longer the exclusive realm of the artist or designer, but the engineer and the medical device maker as well. Its reach extends from the everyday to the athlete, the astronaut, and beyond.

Inside the Wearable Technology Lab (WTL) at the University of Minnesota, you’ll find a host of both hi- and lo-tech equipment. There are sewing machines, knitting machines, welding equipment, soldering guns, 3D printers, tensile testers, two massive tanks of nitrogen that can take an apparel test chamber from cryogenic to super heated in a matter of seconds, as well as a load of traditional engineering equipment. Oh, and there’s a washer and dryer that look like they are from the late ’70s (more on that later).

High on a shelf is a curious jacket that looks surprisingly like the one from the film Back to the Future Part II--because it’s a replica made by the lab to work like that jacket would have, had the film been made in 2015 instead of 1989.

It’s actually the first collaboration by WTL co-directors Brad Holschuh and Lucy Dunne.

“Brad joined just before the date that Marty McFly was to arrive in the future (Oct. 21, 2015),” says Dunne, who founded the wearable lab in 2009. “So we built it for real.”

Nearby is another strange site—a toy plush cat wearing a vest. Dunne is almost apologetic explaining it. “It’s not officially part of the lab—but (the vest holds) a wearable insulin pump for a cat,” she says. “If you have a wearable insulin delivery system, you need to hold it somehow, and cats don’t have pockets, so…”

A place of ideas and possibility

But it’s not all fun and games. From this lab have sprung ideas to improve everything from human health to space travel.

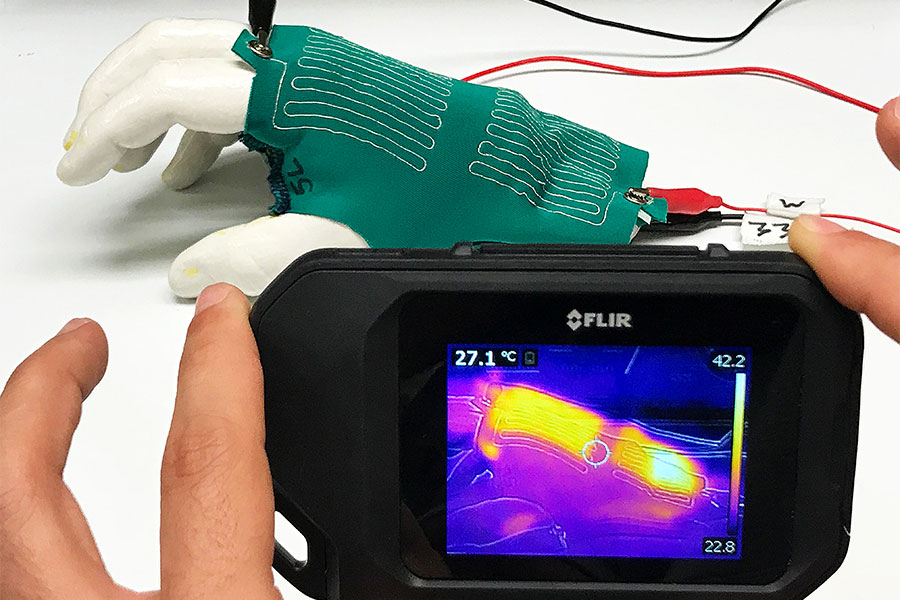

There are creations like a compression vest that can calm children with autism or other sensory processing disorders. And a glove for firefighters which can detect walls and doorways when the smoke is too thick for the human eye to see. And another glove (for astronauts) that can type messages simply by touching a finger to a spot on the hand.

Dunne believes that wearable tech has enormous potential to change the way we deliver health care and monitor patients.

“Wearable technology gives us the ability to remove health monitoring from a clinical setting….so you can go about your daily life and your medical professional might know things about your developing condition(s) before they get to a point where it becomes more serious,” she says.

The lab has a number of products underway in this area, from a vest with an inflatable structure under the arm that can provide a lift assist to children with upper limb mobility issues, to compression pants for astronauts returning to earth who experience blood pooling in the lower limbs. Such a garment also has the potential to help people with a variety of conditions, including lymphedema, orthostatic hypertension, and congestive heart failure.

There is also the world’s sexiest knee brace—a nylon stocking with a sensor woven through the fabric that can alert a person (and their physician) if they are moving in the wrong way.

“One of the challenges is that people don’t have feedback when doing rehab at home—and clinicians don’t know if the patient is actually doing it,” explains Dunne. “They need something that is likely to be worn—that looks and feels like everyday clothing, so people will be more likely to comply.”

Similar technologies could enhance almost any form of rehabilitation, from repetitive strain injuries to detecting and deterring smoking behaviors.

“We could do things like prevent knee replacements 10 years down the line,” says Dunne.

A well balanced lab

Dunne and Holschuh’s skills complement each other’s. Holschuh has a bachelor’s, master’s, and PhD from MIT—all in aerospace engineering, while Dunne’s background was first apparel design, and later electrical engineering and computer science. That balance is a strength of the lab.

“I came from an aerospace department where the way you do a wearable system is that you make a really cool functioning thing, and then you find a way to Velcro it onto someone’s body,” says Holschuh.

"There are so many examples of great technologies that people intended to end up on the body that failed. You need both—wearable technology is both wearable and technology." —Brad Holschuh

“The wearable part of wearable technology is really important, but overlooked—because it’s hard. Our lab has people who are trained in designing things that go on your body first,” he says.

Holschuh says that having WTL within the apparel design program at the College of Design is one of the things that drew him to the University of Minnesota. Most labs are based within engineering programs, and apparel is an afterthought if it’s considered at all.

“Many of our research questions are about the intersection of soft goods and the functioning system, and you can’t discover those problems if you don’t know anything about half of it,” says Dunne.

Holshuch agrees.

“There are so many examples of great technologies that people intended to end up on the body that failed (see Google Glass).... You need both—wearable technology is both wearable and technology,” he says.

To make sure tech and apparel work in harmony, the lab tests its products and clothing in ways a typical person would use them.

“We put people in the clothing and have them operate it,” says Holshuch. We literally have a washer and dryer—and those are test devices for some of our systems. ‘Is it durable?’ ‘Is it washable?’ ‘Is it comfortable?’ These are the make or break [questions] on whether someone is actually going to use the thing,” he says.

Early beginnings

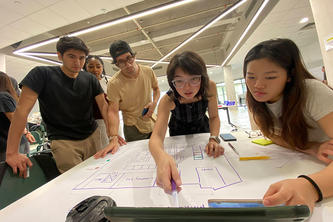

Founded in 2009, long before modern smartwatches, the lab has grown steadily, with students ranging from undergraduates to those in pursuit of a doctorate, like fourth year PhD apparel studies student Rachael Granberry.

Granberry, who has a background in apparel design (minoring in mechanical engineering), splits her time between the Wearable Technology Lab and the Design of Active Materials and Structures Lab within the U of M’s Department of Mechanical Engineering.

“My passion is robotic textiles—textiles that change shape or move in response to a stimulus,” says Granberry. “There are not many people in engineering who are familiar with textile structure, so that’s something I bring from an apparel design background.”

She’s also a NASA space technology research fellow, working on creating compression clothing for astronauts, as well as other applications such as self-fitting garments with shape changing fabrics. This technology could enable applications like robotic exoskeletons, wearable biometric sensing, and consumer shapewear.

{"preview_thumbnail":"/sites/twin-cities.umn.edu/files/styles/video_embed_wysiwyg_preview/public/video_thumbnails/V7FZajZ_ctU.jpg?itok=LL9_IQZJ","video_url":"https://www.youtube.com/watch?v=V7FZajZ_ctU&feature=youtu.be","settings":{"responsive":1,"width":"854","height":"480","autoplay":0},"settings_summary":["Embedded Video (Responsive)."]}

NASA is a frequent partner of the Wearable Technology Lab. Every spring semester, undergraduate students in the lab focus their coursework work on problems presented by NASA. The students do research, prototyping, testing, and eventually develop a product, all while working with NASA mentors.

Holschuh says the lab offers students a range of great opportunities.

“Our students often get placed on cutting edge research projects that either the government or industry have prioritized,” he says. Additionally the lab has worked with industry partners from Oculus (now Facebook Reality Labs) on garments that could support or augment virtual reality, to Kimberly Clark on a leak detecting onesie for babies.

“Every day we have companies that come to us, because as it turns out, the skillset of engineering and apparel together is a really uncommon one, and it’s something that our lab addresses head on,” says Holschuh.

The future of wearables

One of the things you might notice about Holschuh and Dunne is that neither of them wear a traditional wearable device like a wristband or smartwatch.

“They don’t do anything I’m interested in, and they make my hands look small,” jokes Dunne.

More seriously, Dunne says the technology is inherently limited.

“Putting electronics into textiles is a much bigger challenge than making them small and putting them on top of the body,” she says.

“Our lab is really motivated by the promise, but also the challenge and the difficulty, associated with building reliable and functional technology into clothing itself,” she says.

What will the technology look like in the future? That’s being decided now, in places like the University of Minnesota’s Wearable Technology Lab.

-------

Artwork (featuring Brad Holschuh and Lucy Dunne as superheroes) by Mary Ellen Berglund.

Meet the people behind the story

Brad Holschuh

Assistant professor of apparel design, director of the human factors and ergonomics program, and co-director, Wearable Technology Lab.

Lucy Dunne

Professor, director of the apparel design program, and co-director, Wearable Technology Lab.

Rachael Granberry

PhD candidate, apparel studies, and NASA Space Technology Research Fellow.

- Categories:

- Architecture and Design

- Science and Technology