A University of Minnesota-led team has, for the first time, engineered an atomically thin material that can absorb nearly 100% of light at room temperature, a discovery that could improve a wide range of applications from optical communications to stealth technology.

Their paper is published in Nature Communications, a peer-reviewed scientific journal that covers the natural sciences and engineering.

Materials that absorb nearly all of the incident light — meaning not a lot of light passes through or reflects off of them — are valuable for applications that involve detecting or controlling light.

“Optical communications are used in basically everything we do,” said Steven Koester, a professor in the College of Science and Engineering and a senior author of the paper. “The Internet, for example, has optical detectors connecting fiber optic links. This research has the potential to allow these optical communications to be done at higher speeds and with greater efficiency.”

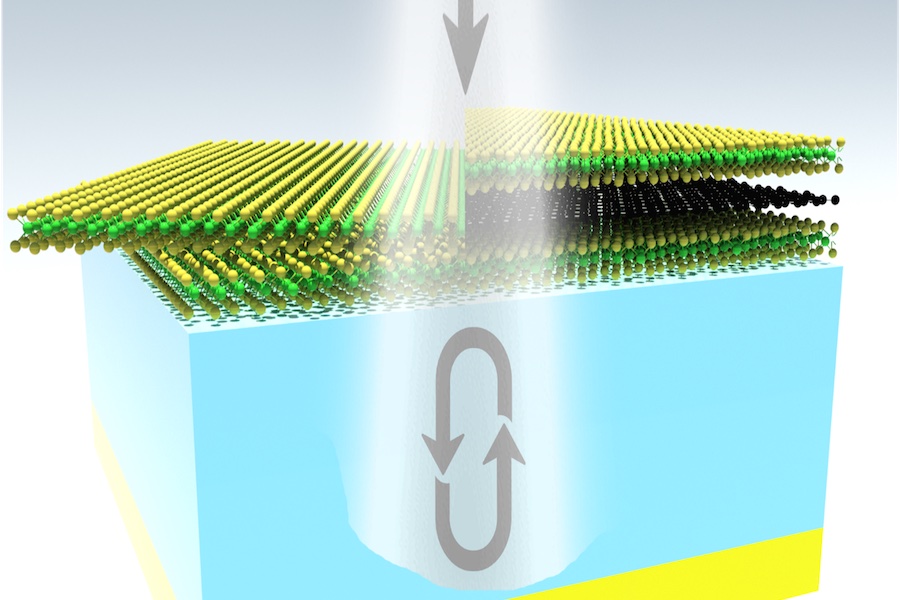

The researchers made this “near-perfect absorber” possible by using a technique called band nesting to manipulate the already unique electrical properties in a material made up of only two to three layers of atoms. Their fabrication method is simple, low-cost and requires no nanopatterning methods, which means it’s easier to scale up than that of other light-absorbing materials being studied.

“The fact that we are able to achieve this near-perfect light absorption at room temperature with only two or three atomic layers of material is really the key innovation here,” said Tony Low, an associate professor in the College of Science and Engineering. “And we were able to do that without using any complex and expensive patterning techniques, which could allow us to make perfect absorbers in a more feasible and cost-effective way.”

This research was funded by the National Science Foundation’s Designing Materials to Revolutionize and Engineer our Future program and the National Research Foundation of Korea. Portions of the work were conducted in the NSF-funded Minnesota Nano Center, of which Koester is also the director.

- Categories:

- Science and Technology

- Science