Filtration devices could make dentist appointments safer during the COVID-19 pandemic

In a new study using 3D holographic imaging, University of Minnesota Twin Cities researchers tested the effectiveness of three filtration devices that can mitigate the spread of aerosols during ultrasonic scaling, a common dental cleaning procedure. The findings could increase health safety in dental offices during the COVID-19 pandemic.

The researchers found that two of the devices—a high-volume evacuator and an extraoral local extractor—were very successful at reducing aerosol spread. This is one of the first studies to use advanced engineering imaging techniques to map the size, distribution, and mitigation of aerosols in dental offices.

The paper was published recently in the Journal of the American Dental Association, a peer-reviewed scientific publication from the world’s largest dental organization.

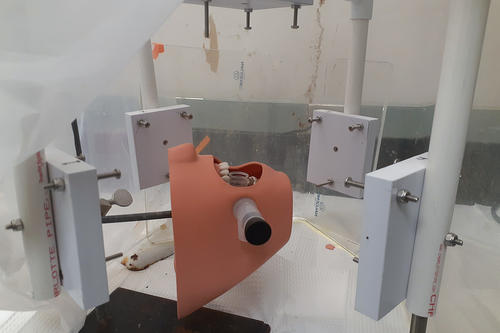

This video first demonstrates the aerosols and splatter released during an ultrasonic scaling procedure on a dental manikin, then shows how this is mitigated when the researchers turned on the extraoral local extractor (ELE) filtration device. Credit: Flow Field Imaging Laboratory, University of Minnesota.

The University of Minnesota research team was led by College of Science and Engineering Professor David Pui and Associate Professor Jiarong Hong in the Department of Mechanical Engineering, with help from Professor Paul Olin, the Associate Dean of Clinical Affairs in the University’s School of Dentistry.

In August 2020, the World Health Organization advised that citizens refrain from going to nonessential dentist appointments due to the higher quantity of COVID-19 aerosols—tiny particles released when we exhale—that could be generated by infected patients during dental procedures. Minnesota dental offices welcomed patients back after the governor’s executive order lifted, but there’s limited data on how many aerosols are actually produced during dental procedures and if those aerosols are infective.

Documented cases of COVID-19 transmission in dental offices are near non-existent, and the University of Minnesota has had over 100,000 appointments since March 2020 without transmission to or from the patients. But until recently, dental clinics were still delivering care at a decreased capacity due to social distancing and waiting periods between appointments to give time for the aerosols to filter out.

“That has a huge impact, not only economically but also in terms of the amount of care we can provide,” Olin said. “We were significantly cutting down on the number of patients we can help in a day. It’s important for us as dentists to understand the aerosols we create and whether they are a mechanism for the transmission of viruses and other things. And if they are, how can we mitigate that? But now that we understand the airflow and aerosol production, our clinics are back at full capacity with the use of mitigation processes and procedures.”

In this study, the researchers looked specifically at aerosol generation during ultrasonic scaling, which involves using a high-speed, vibrating tool to remove tartar, a type of dental plaque, from a patient’s teeth. Using a dental manikin and thermoplastic teeth—and with real dental hygienists performing the procedure—the researchers used holographic imaging to map the size and distribution of aerosols released.

“This technique allows us to look at suspended particles in the air or in liquids,” explained Hong, whose lab specializes in 3D imaging of particles and flow. “If you look at conventional microscopy, you put a particle on a slide and have to use a microscope and manually focus in on the object in order to see that particle. Holography imaging allows us to directly see the particles as they’re moving in the air.”

Then, the researchers tested three devices that aim to filter the aerosols from the air. These included a saliva ejector, a high-volume evacuator (HVE)—both tools that dentists already use regularly to remove saliva after rinsing—and an extraoral local extractor (ELE), a vacuum-esque mechanism made by Donaldson Company, an industry collaborator of the University’s Center for Filtration Research.

They found that the ELE and HVE were most effective at filtering out the particles, reducing the amount of aerosols by 96 and 88 percent, respectively. The researchers also found that using combinations of the different devices doesn’t necessarily lead to better particle removal. For example, using the ELE alone is more efficient than combining it with the saliva ejector or the HVE. And, the positioning of the suction devices matters too.

The researchers hope that their findings can guide dental professionals on what strategies they can use to keep COVID-19 from spreading in their offices.

“The Journal of the American Dental Association is obviously a very important journal for the dental community,” said Pui, who is also a University Regents Professor and the LM Fingerson/TSI Chair in Mechanical Engineering. “By publishing our study there, dentists can review our findings and know what methods they can use to control the potential spreading and help mitigate the spray from dental operations.”

This study also paves the way for further exploration of this topic. The engineering researchers are already working with the School of Dentistry on a different project that measures aerosol generation from another dental tool, a high-speed hand piece. They also plan to more accurately model how aerosols travel in dental clinics in order to provide better guidelines for how much time dentists can allow between patient appointments.

In addition to Pui, Hong, and Olin, other University of Minnesota contributors to this research include mechanical engineering senior research scientist Qisheng Ou and graduate student Rafael Grazzini Placucci, who both helped design and implement the experiments; mechanical engineering research scientist Siyao Shao; professors Judy Danielson and Gary Anderson in the Department of Developmental and Surgical Sciences; Professor Paul Jardine in the Department of Diagnostic and Biological Sciences; and dental laboratory production manager John Madden in the Department of Restorative Sciences. Industry collaborators at Donaldson Company include Qinghui Yuan, the director of modeling and data science, and Timothy Grafe, the company’s vice president.

This study was supported in part by the Center for Filtration Research at the University of Minnesota.

Read the full article entitled, “Characterization and mitigation of aerosols and spatters from ultrasonic scalers,” on the ScienceDirect website.