When [U of] M Health Fairview contacted biomedical engineering (BME) professor Steven Saliterman for help designing disposable gowns for health workers, Saliterman assembled 18 of his biomedical engineering students. Within two weeks, they had created a safe, functional gown design that could be rapidly manufactured for use in Minnesota hospitals.

Now, local companies Red Fox Innovations and Polar Plastics are rapidly producing the gowns—at a rate of 5,000 to 10,000 per day—and shipping them to M Health Fairview clinics.

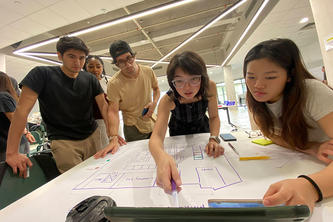

Students led the entire process from start to finish. They created drawings and prototypes, sourced a Food and Drug Administration-certified material, visited plants, and found local manufacturers. They worked with M Health doctors and nurses, professors in the U of M’s College of Design, and 3M to finalize the design.

“I was able to gain insight into all aspects of taking a project from day one to the finish line,” says Sam Newell, who as a BME senior worked with Red Fox to coordinate manufacture of the gowns. “The exposure I gained in this project was as valuable as any course work I’ve done here at the University.”

“I learned as much or more than [I did] in my senior design class,” says James Kerber, another BME senior on the project. “However, this was done in [only] three weeks. It’s a valuable experience that I can talk about in nearly any interview for many years to come.”

The team’s goal is to produce 350,000 gowns in the coming months, ultimately providing Personal Protective Equipment (PPE) for 35,000 employees in the M Health Fairview system.